Full-Service Custom

Metal Fabrication Service

IGH Steel is a full-service custom metal fabricator that is backed by a quality service department and over 60 employees.

We have the capacity to take on a variety of different types of projects. We can design and manufacture one part, but we also have the capability to handle tens of thousands. Whatever you need, we can get it done.

Expert Custom Metal Fabrication Solutions

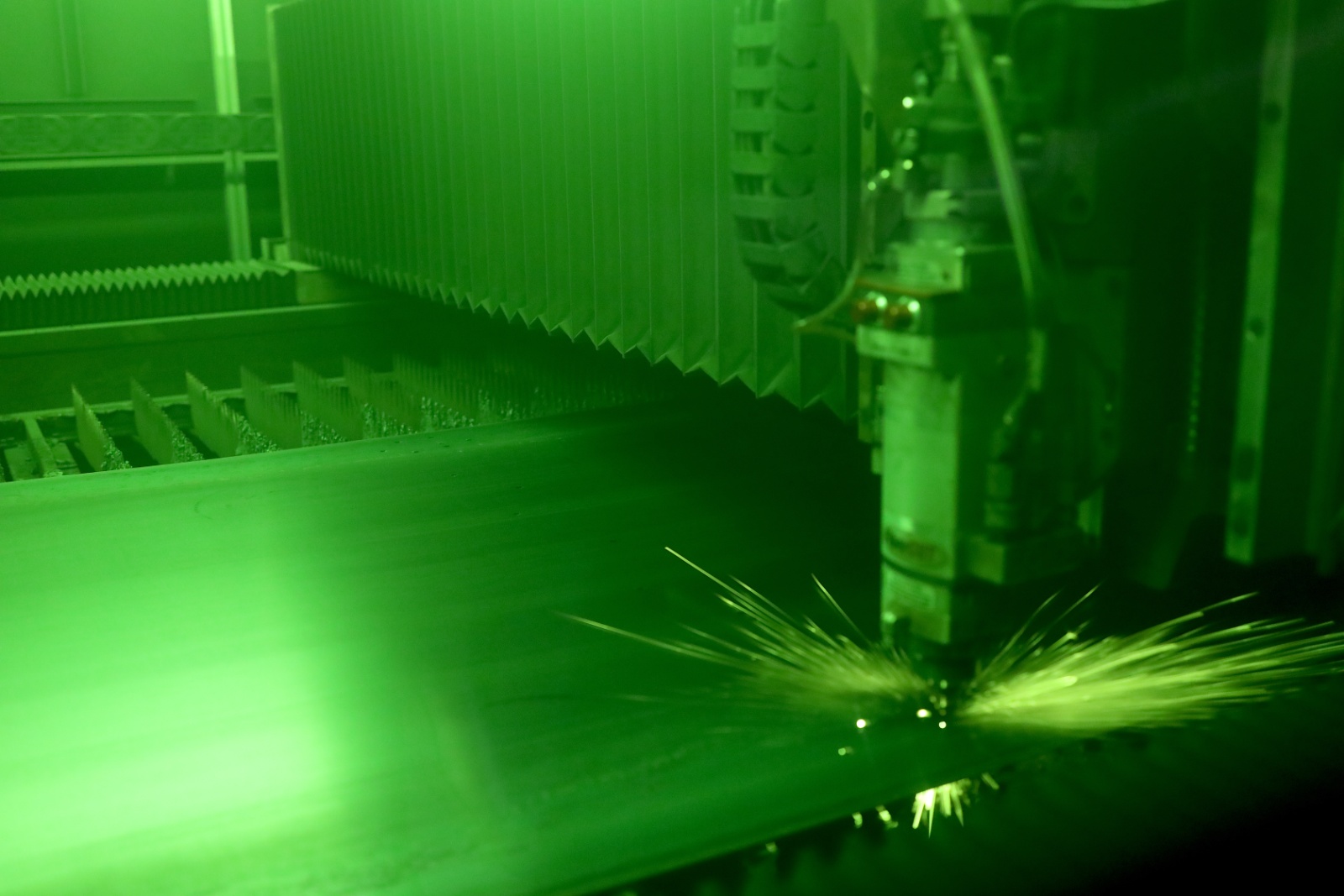

Laser Cutting

We offer fast and precise laser cutting of a wide variety of materials and thicknesses.

Our new Cincinnati 8k Fiber Optic Laser enables us to process material faster, thus increasing our capability and accelerating our response times. This also increases our capabilities and helps us better serve our customers and continue to provide quality products.

Our Lasers:

- CL-980 8k Fiber Optic Cutting Laser with 2×4 meter table (with automation)

- CL-980 8k Fiber Optic Cutting Laser with 2 x 4 meter table

- CL-440 4k CO2 Laser with 5’x10’ table

Capabilities:

- Mild Steel: up to 1”

- Stainless: up to 1”

- Aluminum: up to 1”

- Brass: up to ¼”

- Copper: up to ¼”

Forming

Our skilled brake operators can handle both large and small batch orders. Our experienced staff manages and operates the machines and tooling for all projects to perform the bends that the part needs. We can handle any level, from simpler prototypes to large, custom production runs.

Machinery:

- Qty 2 – 175 ton brakes with 12 ft beds

- Qty 2 – 90 ton brakes with 8 ft beds

Features:

Auto Crowning, 5 axis CNC backstop control with high precision tooling.

Includes tube bending and rolling capabilities (50” wide, ¼” thick carbon steel).

Welding

We offer multiple types of welding with several manual welding stations.

Manual Welding We Offer:

- Metal Inert Gas (MIG)

- Tungsten Inert Gas (TIG)

- Stick

- Spot welder

- Robotic welding

Certifications:

Our welders are talented and certified. However, if you require a specialty certification for your project, we can arrange that

Drilling

We have the capability to create holes in solid materials with hole location tolerances up to +/- .030, along with tapping and creating countersinks.

Machines Available:

- CNC Mill

- Drill Presses

- Tap arms

- Radial arm drill

- Light mills

Powder Coating

Powder coating is the process of applying dry powder to metal. The powder is electrically charged to bond with the part, then cured in the oven for a long-lasting, durable finish. It’s also safer for the environment than standard paint.

We have the ability to steam clean, sandblast, and powder coat your finished product all in-house. We have the capability to run both one-off parts and thousands of parts, and we currently have an array of colors and textures in stock.

We can run parts up to 8’ long, 30” wide, and 40” tall.

Equipment:

- Gema Optiflex 2 Paint Gun

- Skat Blast Sandblasting

- Powder Coating line for higher volume product lines

- Batch System for large pieces or smaller volume

Separate Options:

- Sand blasting available

- Utilize multiple vendors for powder coat including Sherwin Williams, PPG, and Akzo Nobel

- We use a Phosphate dry steam cleaning system in both of our Batch and Line processes

Custom Packaging

IGH Steel offers a production line that can create, package, and ship your kit. This tends to save our customers a lot of time and money and offers an added layer of quality and convenience.

Sawing

With our CNC bundle saw, we are able to cut to any project’s specification using automation. We are also able to handle multiple tubes instead of one at a time, saving time and money.

Final Assembly

We can help source hardware needs as well as assemble final products exactly how you’d like them shipped. This can save time, money, and labor for the customer.

Engineering

IGH Steel has multiple design engineers on staff who can make your vision a reality, leveraging SolidWorks and Auto CAD software.

We can help produce prints and customize or breakout assemblies as needed. If you can dream it, we can create it.

Additional Equipment

In addition to our services, we also have:

- Sheet roller

- Plate roller

- PEM machine

- Stamp press

- Shear

- Tube Bender